Managing the inventory of a business is probably one of the most overlooked functions. Many leading businesses can be found guilty of improperly handling their raw materials. This not only compromises the efficiency of the production process but also leads to financial losses.

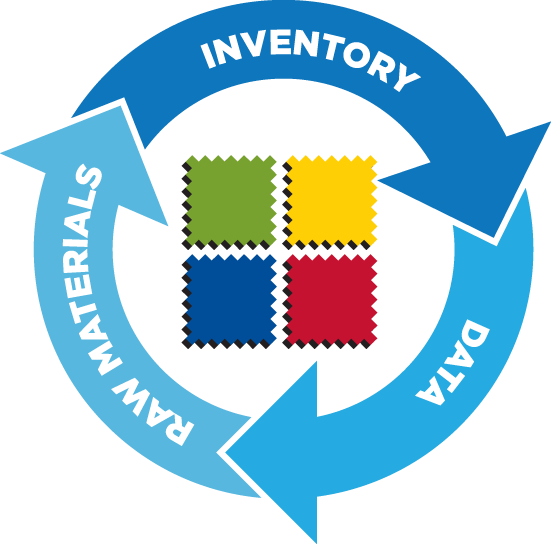

In the last few years, a new specialized area called Materials Management has come to the fore. It highlights the progressive management or raw material inventory in a way that-

- Helps in the reduction of wastages

- Cuts down on labor inefficiency

- Promotes integration across verticals

- Clears warehouse space and areas

- Reduces transportation costs

In short, effective materials management can bring a number of benefits to a business organization. In this article, we look at some of the most common materials management mistakes and pitfalls businesses make.

List of 5 Common Materials Management Mistakes Made by Businesses

- Problems in Determining Raw Materials and Forecasting-

Raw material supply and production cannot be the same at all times. Some months it is bound to come down, whereas in other months it shows a marked increase.

A lot of this might also have to do with seasonal variations and the need for the business product. Many businesses make forecasting mistakes as far as materials management is concerned. This makes them order more inventory and leads to wastages.

Raw materials can get spoiled as they come with an expiry date. There can also be thefts or weather issues and damages that can deplete them.

- Choosing the Wrong Inventory Management Software-

In recent years a number of businesses have sought help from technological advancements and solutions. There exist multiple inventory management software and solutions.

However, most of them are not that great in terms of integrations, accurate results, and data projections. It is necessary that businesses must choose the best materials management software. This can help in attaining all the benefits that come with proper management.

The software should come with excellent customer service and support. It also needs to be simple and flexible enough for everyone in the organization to get the hang of it.

- Not Training the Employees in Materials Management-

It should be pointed out that proper rolling out of materials management is not something that is the responsibility of any single individual. This is a habit or culture for the entire organization.

When businesses start to use materials management software, they need to train their employees accordingly. This training would help everyone understand the end objectives.

Once all the employees concerned in the act are on the same page, a business can expect heightened levels of productivity. This can have a direct impact on profitability.

- Avoiding the Learnings from Data Analytics-

Modern businesses need to become rooted in data if they want to achieve successful results. Without it, you will be at the mercy of subjective decision-making, that might or might not work out. Data analytics and learnings should form the bedrock of all business processes.

Using great materials management software, understanding what the ERP is telling you, and hiring experts to draw trends, forecasts and projects are integral.

Using data can help inform crucial decision-making at multiple levels. It can help with ordering raw materials at the right time and according to the demands of the customers.

- Not Focussing on the Various Stakeholders in the Process-

Materials management depends on several external variables. In other words, there are various stakeholders where coordination plays a major role. Right from the transportation company to the raw material sourcing company, everyone needs to be on the same page.

This is where technology can come to the aid of modern businesses. It can help in improving the various stages, methods, and steps that come with the process.

For the most efficient set-up, it is essential that on the software front, there is integration. This will ensure that one command reaches all the stakeholders at the same time.

The Bottom Line

By avoiding the above-mentioned materials management problems, businesses can hope to improve their entire production process. If you have any more questions that you would like to know about materials management, let us know in the comments section below. We will be more than happy to help you out in this regard.