Managing maintenance, repair and operations (MRO) inventory is a crucial aspect of any manufacturing or industrial operation. MRO inventory includes spare parts, tools, safety supplies and other items needed to keep equipment and facilities running smoothly. While some companies choose to handle MRO inventory management in-house, others opt to outsource this function to a third-party partner. There are valid arguments on both sides of the outsourcing question. Carefully weighing the pros and cons of each approach can help operations and supply chain managers make the best choice for their unique situation.

In-House MRO Inventory Management

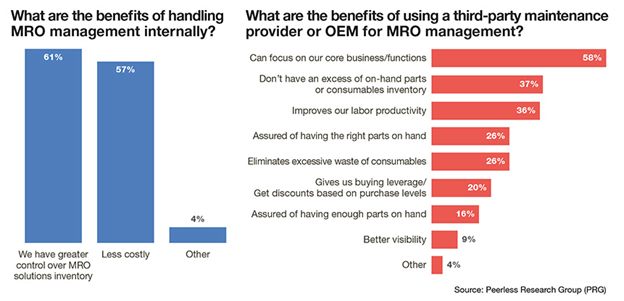

Retaining full control over MRO inventory and management processes is often viewed as the default option. There are several potential advantages to keeping this crucial function in-house:

Better understanding of internal needs

Company employees with an intimate understanding of the manufacturing or production environment and equipment are already on hand. Leveraging this institutional knowledge for MRO inventory decisions can be beneficial. Workers know which spare parts see the most demand. They understand what tooling supplies are needed for maintenance procedures. With this insight, they can make informed choices about stock levels, replenishment timing and other inventory policies.

- Tighter integration across departments

Closer coordination between inventory management, maintenance, production and other internal teams is facilitated by keeping MRO inventory responsibilities in-house. For example, maintenance teams can provide input to ensure needed spare parts are in stock. Communicating pain points or changes in demand becomes easier when working with internal colleagues versus an outside supplier.

- More control over inventory spending

In-house MRO inventory management provides greater oversight and control related to spending and budgets. Rather than relying on an outsourced provider to make purchasing decisions, the company retains authority over what MRO supplies are procured and at what cost.

- Enhanced agility and responsiveness

Needed tools, spare parts or other MRO inventory items can typically be procured more quickly through internal channels. Streamlined communication reduces delays. If an urgent request emerges on the production floor or in the maintenance shop, it can be prioritized and fulfilled rapidly when working directly with the internal MRO management team.

- Better security over proprietary information

When MRO inventory management is handled externally, appropriate non-disclosure agreements should be in place. However, some companies are still wary of sharing details about their proprietary equipment and facilities with outside parties. Keeping these activities internal reduces concerns about protecting trade secrets or intellectual property.

Outsourced MRO Inventory Management

While the benefits of in-house management are compelling, outsourcing MRO inventory tasks also has advantages in certain scenarios:

- Cost savings and economies of scale

Outside MRO inventory management providers can achieve lower per-item costs by aggregating demand across their client base. The sheer purchasing power and discounts they can negotiate may be difficult for an individual company to match. These savings are passed along to clients. The outsourced approach also avoids having to pay for dedicated in-house staff and other fixed overhead expenses associated with self-managed MRO inventory activities.

- Access to advanced IT systems

Sophisticated inventory management software tools may be leveraged by third-party MRO specialists, representing an investment that would be challenging for an individual company to justify. Integrated systems for forecasting, optimizing stock levels, automating reorders and mining purchasing data can drive efficiency. Clients benefit through streamlined processes and insightful analytics.

- Experienced staff with specialized expertise

Outsourced inventory management providers employ dedicated experts focused solely on mastering MRO inventory planning and logistics. These specialists hone their skills by collaborating with an array of clients over time. Tapping into this expertise can be an advantage compared to cultivating such competencies internally. Professional certification programs in areas like supply chain management and inventory control validate these providers’ capabilities.

- Improved maintenance team productivity

Liberating maintenance teams from inventory duties related to sourcing, stocking and managing MRO supplies enables them to focus their efforts where they add the most value. Their time is freed up to run preventive maintenance programs, address equipment repairs, update technical documentation and enhance overall operational effectiveness. The opportunity cost of not outsourcing inventory tasks isforegone productivity gains.

- Reduced carrying costs

In some cases, outsourced MRO inventory management can reduce overall inventory investment and related carrying costs. Providers can consolidate stock in fewer locations, avoiding duplication across multiple on-site stores. Just-in-time inventory and stock pooling approaches also trim excesses. The result is leaner overall inventory. Even when inventory reductions seem minor, the cumulative effect on freed up working capital can be substantial.

Key Considerations for Making the In-House vs. Outsourcing Decision

When approaching the choice between in-house and outsourced MRO inventory management, key factors to weigh include:

Cost impact – How will direct expenses as well as opportunity costs differ between the two models?

Staff capabilities – Does sufficient in-house expertise exist? Is adequate training feasible?

Technology requirements – What inventory management tools are required? Can existing systems provide them?

Control needs – How much direct oversight is necessary around purchasing and stock decisions?

Agility needs – How critical is response time if high-priority part or tool requests emerge?

Security concerns – Is protecting proprietary data regarding equipment and supplies essential?

Service requirements – Are supplementary value-added services like inventory analytics important?

Scalability needs – Is there significant growth or variability expected in MRO inventory volumes?

There is no universal right or wrong answer regarding in-house versus outsourced MRO inventory management. The optimal approach depends on each company’s unique needs and strategic priorities. With rigorous evaluation of the key trade-offs, operations managers can make fully-informed sourcing decisions aligned to their business objectives.

Conclusion

MRO inventory management is a complex undertaking involving trade-offs between cost, control, capabilities, and other factors. There is no universally superior choice between handling MRO inventory in-house versus outsourcing. The optimal approach depends on each company’s unique priorities and strategic needs. By carefully weighing the pros and cons of each option through an objective, business-focused analysis, organizations can make fully-informed MRO inventory sourcing decisions tailored to their operations. The right choice comes down to diligent assessment of requirements and prudent planning to select the model that best fits the organization’s goals and circumstances.