Energy is expensive and vital in most industrial manufacturing processes. That’s why you must ensure you use it optimally and not waste it. You can best achieve this by using effective heat exchangers. The need to ever improve a heat exchanger’s performance is always increasing. As a result, energy-intensive industries are always looking for more effective ways to achieve this goal while maintaining or cutting costs. Shell and tube heat exchangers are the market’s most popular types of heat exchangers. And if you are wondering how to improve their efficiency, here is what to do.

Temperature Difference

Changes in flow direction on the side passes of a shell-and-tube heat exchanger can affect the temperature differences. You might also experience a temperature cross where the exchanger splits into two, significantly lowering the required area. Too much pressure drop will lower the condensing fluid’s saturation temperature. If this is your hot fluid, you can be sure it will bring down the heat transfer. This is vital in decreasing the tube passes and can help increase your heat exchanger’s efficiency.

Increasing Velocity

You can decrease the flow area on the tube side by increasing the number of tubes per pass. Alternatively, you can change the diameter or add baffles on the shell side. However, this will come at an additional cost of a drop in the pressure of the fluids.

Decrease The Leakage Streams

A high drop in shell side pressure will result in shell side fluid looking for alternative routes. These gaps between the shell and bundle will lead to thermal ineffectiveness. This can be a result of increasing or adding baffles. On the other hand, decreasing the baffles can optimise heat transfer. Furthermore, employing different techniques to block these leakages can improve heat transfer efficiency.

Periodic Cleaning

Heat exchangers also need cleaning to maximise their efficiency. Periodic cleaning helps flush out any accumulated dirt and debris, which could lower the heat exchanger’s efficiency. Cleaning your heat exchanger involves draining both sides of the exchanger and isolating it from the system fluid. Using water, you can flush out both sides until the water coming out runs clear. Then, to achieve the best results, you can flush in the opposite direction of the regular flow of fluids. Once all the debris and dirt are out, you can pass a cleaning agent using the solution tank. Afterwards, flush the whole system with clean water until the discharge is clear.

Jet Impingement

This involves directly heating or cooling the heat exchanger’s solid surface by spraying a fluid through a nozzle. The sprayed fluid will directly impinge on the solid wall. Because the boundary layer is thin and the flow path is also short, the convective heat transfer will increase significantly. When the spray fluid impinges on the hot surface, and the heat flux is high enough to cause boiling, it is referred to as the impingement heat transfer of a two-phase jet.

Enhanced Surfaces

When handling most condensation or clean boiling applications, enhancing the surface can greatly improve the heat exchanger’s coefficient. Heavy equipment manufacturers of various industries commonly use these techniques.

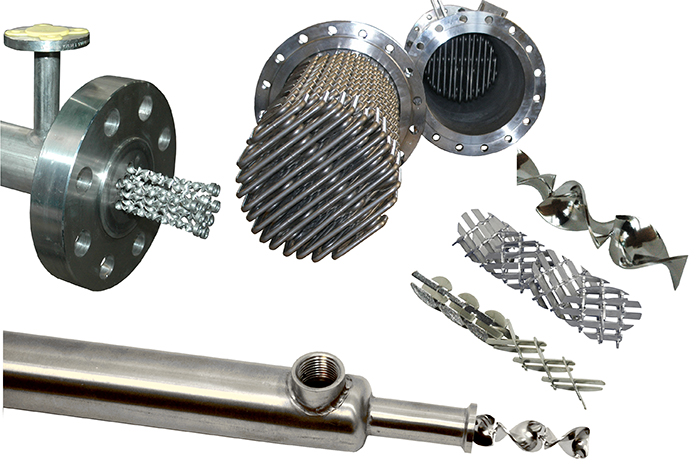

Adding A Rotating Flow Device

A rotating flow has a centrifugal force that will make the heat exchanger fluids produce secondary circulation. Examples of a rotating flow device include a metal spiral wire, a Vortex generator or a twisted iron. They can make a fluid with a certain pressure move in a tangent direction in the tube, creating violent rotational movements. As a result, the extent of the heat transfer enhancement is directly related to Reynold’s number. With a certain heat source temperature, the convective heat transfer coefficient increases with value and reaches a certain maximum value.

Implement Maintenance Practices

One of the outstanding ways to increase your heat exchanger efficiency is by practising proper maintenance practices. This will help avoid leakages, fouling, and blockages in the shell and tube heat exchanger. The absence of effective maintenance practices or failure to follow through will lead to higher energy costs, erosion problems, and cross-contamination of the heat exchanger fluids.

Pigging

This is a type of heat exchanger cleaning, specifically, an offline cleaning technique. It involves using bullet-like equipment put in each heat exchanger tube and then pushed down using high-air pressure. It’s an effective way to improve your heat exchanger’s efficiency, but you can also use other offline cleaning techniques like hydro-launching, chemical cleaning, or hydro-blasting. To get the most out of this technique, you must maintain a periodic cleaning schedule. In turn, you will achieve optimal efficiency.

The efficiency of a heat exchanger is essential as it helps cut down on cost and energy consumption. Thus, it’s vital always to analyse and address any issues that may arise and could affect the efficiency of the heat exchanger. Leaving minor problems unchecked could lead to irreparable damages that could affect the heat exchanger’s efficiency. And, as expensive as this equipment is, that can lead to some major losses.